How does sheet metal customization transform into precision components through customized processes?

Release Time : 2025-10-10

In modern industrial manufacturing, sheet metal parts are ubiquitous, from precision instrument housings to large machinery frames, from telecommunications cabinets to new energy vehicle battery boxes. These seemingly ordinary "metal boxes" or structural parts actually undergo a complex transformation from raw materials to high-precision functional components. This is inseparable from the highly flexible, precise, and efficient manufacturing method of sheet metal customization.

1. Starting Point: From Customer Needs to Precision Design

The first step in sheet metal customization begins with a deep understanding of customer needs. Customers may only provide a vague functional concept or sketch, and professional sheet metal customization service providers must transform this into manufacturable engineering drawings. This process relies on advanced CAD software. Engineers perform 3D modeling and structural optimization based on parameters such as the usage scenario, installation space, load-bearing requirements, and heat dissipation needs. Design not only concerns the appearance but also involves details such as bend radius, hole accuracy, tolerance matching, and weld placement.

2. Cutting: Laser Precision "Tailoring"

After the design is finalized, the first step in processing is cutting. Traditional shearing machines are no longer able to meet the demands of processing complex shapes. Modern sheet metal customization widely utilizes fiber laser cutting technology. The laser beam, when focused, boasts extremely high energy, enabling micron-level precision cutting in sheet metal. Whether it's circular or shaped holes or intricate hollow patterns, these can be created in a single pass, resulting in smooth, burr-free edges. Laser cutting also supports flexible production, eliminating the need to change molds; simply importing a different drawing allows for product switching, making it particularly suitable for small-batch, high-variety customization. Laser "carving" a flat sheet of metal takes the initial shape of the component's outline, marking the first step toward becoming a precision part.

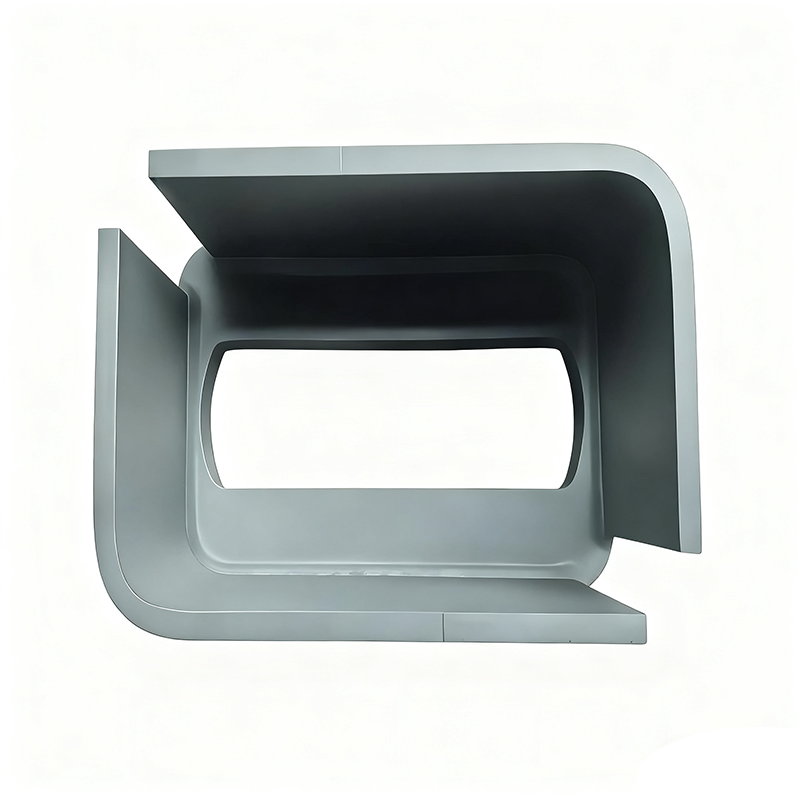

3. Forming: Bending to Create Three-Dimensional Structures

The cut sheet metal is still two-dimensional and requires three-dimensional shaping using a CNC press brake. Bending is a critical process in sheet metal fabrication, directly impacting the dimensional accuracy and assembly performance of the final product. Modern CNC press brakes automatically adjust the bending angle, pressure, and sequence according to pre-set programs, achieving precise forming at multiple angles and in multiple passes. For example, a computer chassis requires multiple bends to form its housing. Each bend must be precise, otherwise subsequent welding or assembly will be difficult. Through programmable control, machines ensure consistency across every product, truly achieving high-precision manufacturing with "one-size-fits-all."

4. Connection and Auxiliary Processing: Building Complete Functionality

After bending and forming, a series of auxiliary processes are required, such as punching, tapping, welding, and riveting, to enable mounting, wiring, and heat dissipation. CNC punching machines can quickly create mounting holes in designated locations; robotic welding ensures uniform and secure welds; and specialized processes such as flanging, embossing, and countersinking further enhance the component's functionality and aesthetics. Complex structures may also require component assembly and subassembly, combining multiple sheet metal parts into a complete functional module, such as a control cabinet or equipment bracket.

5. From "Sheet Metal" to "Component": The Core Value of Customization

An ordinary sheet metal sheet is ultimately transformed into a precision component that meets specific functional, dimensional, and quality requirements. This process embodies the core advantages of sheet metal customization: high flexibility, controllable precision, rapid response, and support for small-batch, custom-made production. It transcends the limitations of traditional mass production, enabling companies to develop personalized, differentiated products at a lower cost. It is widely used in high-end manufacturing sectors such as communications, power generation, healthcare, rail transit, and new energy.

Sheet metal customization is more than just processing; it's a form of creation. Through intelligent and sophisticated process chains, it transforms cold sheet metal into the "skeletal" and "exterior" that underpin modern industry. In the future, with the advancement of automation, digitalization, and intelligent manufacturing, sheet metal customization will further advance toward a new stage of efficiency, greenness, and intelligence, continuously empowering the manufacturing industry.

1. Starting Point: From Customer Needs to Precision Design

The first step in sheet metal customization begins with a deep understanding of customer needs. Customers may only provide a vague functional concept or sketch, and professional sheet metal customization service providers must transform this into manufacturable engineering drawings. This process relies on advanced CAD software. Engineers perform 3D modeling and structural optimization based on parameters such as the usage scenario, installation space, load-bearing requirements, and heat dissipation needs. Design not only concerns the appearance but also involves details such as bend radius, hole accuracy, tolerance matching, and weld placement.

2. Cutting: Laser Precision "Tailoring"

After the design is finalized, the first step in processing is cutting. Traditional shearing machines are no longer able to meet the demands of processing complex shapes. Modern sheet metal customization widely utilizes fiber laser cutting technology. The laser beam, when focused, boasts extremely high energy, enabling micron-level precision cutting in sheet metal. Whether it's circular or shaped holes or intricate hollow patterns, these can be created in a single pass, resulting in smooth, burr-free edges. Laser cutting also supports flexible production, eliminating the need to change molds; simply importing a different drawing allows for product switching, making it particularly suitable for small-batch, high-variety customization. Laser "carving" a flat sheet of metal takes the initial shape of the component's outline, marking the first step toward becoming a precision part.

3. Forming: Bending to Create Three-Dimensional Structures

The cut sheet metal is still two-dimensional and requires three-dimensional shaping using a CNC press brake. Bending is a critical process in sheet metal fabrication, directly impacting the dimensional accuracy and assembly performance of the final product. Modern CNC press brakes automatically adjust the bending angle, pressure, and sequence according to pre-set programs, achieving precise forming at multiple angles and in multiple passes. For example, a computer chassis requires multiple bends to form its housing. Each bend must be precise, otherwise subsequent welding or assembly will be difficult. Through programmable control, machines ensure consistency across every product, truly achieving high-precision manufacturing with "one-size-fits-all."

4. Connection and Auxiliary Processing: Building Complete Functionality

After bending and forming, a series of auxiliary processes are required, such as punching, tapping, welding, and riveting, to enable mounting, wiring, and heat dissipation. CNC punching machines can quickly create mounting holes in designated locations; robotic welding ensures uniform and secure welds; and specialized processes such as flanging, embossing, and countersinking further enhance the component's functionality and aesthetics. Complex structures may also require component assembly and subassembly, combining multiple sheet metal parts into a complete functional module, such as a control cabinet or equipment bracket.

5. From "Sheet Metal" to "Component": The Core Value of Customization

An ordinary sheet metal sheet is ultimately transformed into a precision component that meets specific functional, dimensional, and quality requirements. This process embodies the core advantages of sheet metal customization: high flexibility, controllable precision, rapid response, and support for small-batch, custom-made production. It transcends the limitations of traditional mass production, enabling companies to develop personalized, differentiated products at a lower cost. It is widely used in high-end manufacturing sectors such as communications, power generation, healthcare, rail transit, and new energy.

Sheet metal customization is more than just processing; it's a form of creation. Through intelligent and sophisticated process chains, it transforms cold sheet metal into the "skeletal" and "exterior" that underpin modern industry. In the future, with the advancement of automation, digitalization, and intelligent manufacturing, sheet metal customization will further advance toward a new stage of efficiency, greenness, and intelligence, continuously empowering the manufacturing industry.