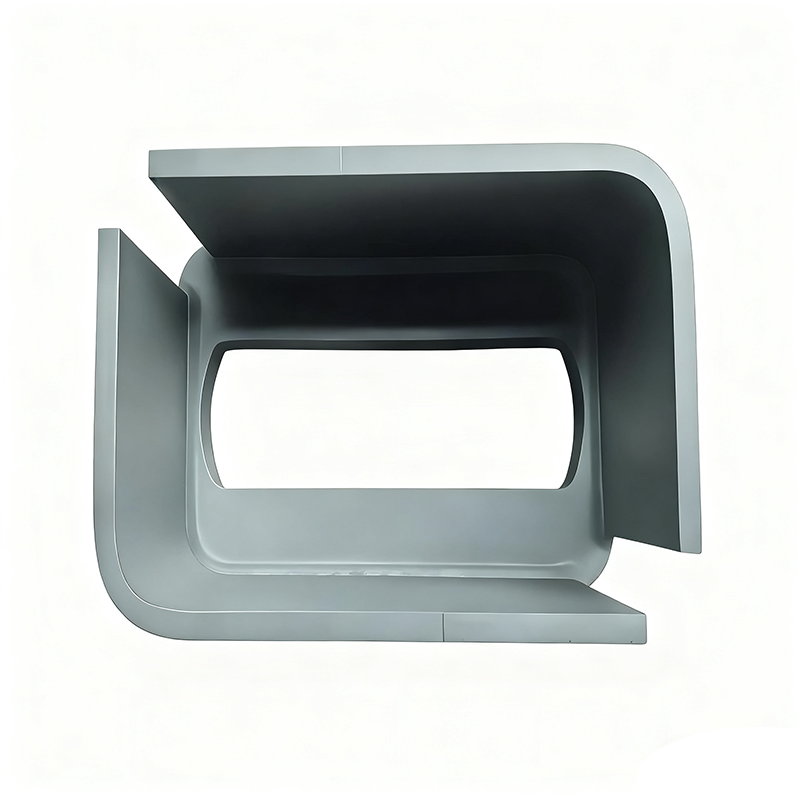

How to ensure the sealing of the metal seams during sheet metal customization?

Release Time : 2025-10-23

In sheet metal customization, the sealing performance of sheet metal splicing directly impacts the product's waterproofness, dustproofness, and structural stability. To ensure the tightness of joints, a comprehensive approach encompassing material selection, process design, processing control, and quality inspection is required to form a systematic sealing assurance system.

Material matching is the foundation of sealing performance. When splicing sheet metal, compatible material combinations should be selected based on the intended use environment. For example, when splicing stainless steel and aluminum alloy, electrochemical corrosion must be considered, which can be addressed through coating isolation or the use of corrosion-resistant interlayers. Furthermore, sheet metal thickness must be uniform to avoid stress concentration at the joint due to thickness variations, which can cause cracking or deformation. For example, when splicing thin sheets, it is preferable to use sheets from the same batch and specification to minimize the impact of material property fluctuations on sealing.

The splicing process design must balance strength and sealing performance. Common splicing methods include welding, riveting, clinching, and gluing, each of which has varying impacts on sealing performance. Welding achieves optimal sealing by melting metal at high temperatures, but welding parameters must be carefully controlled to avoid defects such as porosity and cracks. Riveting mechanically secures the sheet metal and is simple to operate, but may leave small gaps at the joints, requiring sealant. Clinching secures the sheet metal edges by folding and snapping them together, eliminating the need for additional materials. However, the folding angle and snapping force must be precisely controlled. Gluing relies on the adhesive's bonding strength and is suitable for dissimilar materials or complex structures, but requires strict control of adhesive thickness and curing conditions. In practice, composite processes, such as post-weld gluing, are often used to achieve a balance between strength and sealing.

Precision control is crucial during sheet metal customization. During the blanking stage, accurate sheet dimensions and smooth, burr-free edges are crucial to avoid misalignment of the joints due to dimensional deviations. During bending, the bending radius must be adjusted according to the sheet metal thickness to prevent cracks caused by excessive bending. For example, a thin sheet with a bending radius that is too small may cause the sheet to break, while a radius that is too large may affect the fit of the joint. When splicing, special clamps are used to secure the panels to ensure alignment and minimize assembly errors. Furthermore, processing equipment requires regular maintenance to maintain stable accuracy and prevent wear and tear that could degrade the joint quality.

Sealing is crucial for improving airtightness. After splicing, the joints must be sealed. Common methods include applying sealant, applying sealing strips, and polishing the weld seams. When applying sealant, choose a metal-compatible sealant, such as silicone or polyurethane, and ensure an even, bubble-free application. When applying sealing strips, tailor the strips to the shape of the joints to ensure a tight fit. Polishing weld seams removes oxide layers and burrs, improving surface smoothness and providing a good foundation for subsequent sealing.

Quality inspection is the final line of defense for ensuring airtightness. After splicing, the joints must be verified for airtightness through visual inspection, penetrant testing, and airtightness testing. Visual inspection can reveal obvious defects such as cracks and gaps. Penetrant testing involves applying a penetrant and observing whether it penetrates the joint to determine sealing quality. Hermetic testing involves applying pressure or vacuum to detect leaks at the joint. For example, in pressure vessel manufacturing, helium mass spectrometer leak detectors are often used to detect small leaks and ensure that joint sealing meets standards.

The impact of environmental factors on sealing quality cannot be ignored. High temperatures, high humidity, or corrosive environments can accelerate the aging of sealing materials, leading to a decrease in sealing quality. Therefore, in sheet metal customization, it is important to select weather-resistant sealing materials and optimize process design based on the operating environment. For example, in humid environments, waterproof adhesives can be used or the coating thickness at the joints can be increased. In high-temperature environments, high-temperature-resistant sealing materials are required to prevent softening and seal failure.

Ensuring sealing quality in sheet metal splicing during sheet metal customization requires a comprehensive approach encompassing multiple dimensions, including material matching, process design, processing control, sealing treatment, quality inspection, and environmental adaptability. By optimizing process parameters, strictly controlling quality and selecting appropriate sealing materials, the sealing performance of the joints can be significantly improved, providing reliable protection for the long-term stable operation of the product.