Can wafer mounting plates support the stringent requirements of semiconductor manufacturing with micron-level precision?

Release Time : 2026-01-26

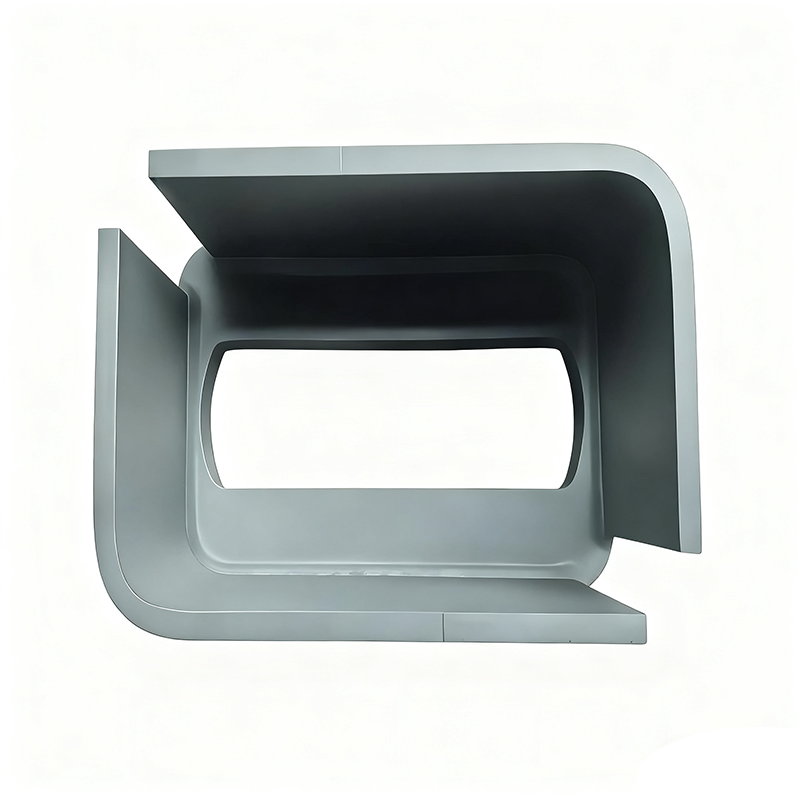

In the highly precise industrial field of semiconductor manufacturing, even a deviation of one nanometer can affect chip yield and performance. As the component that positions and supports the wafer in critical processes such as etching, deposition, inspection, and packaging, the wafer mounting plate (also known as a wafer chuck or carrier plate), while not directly involved in circuit formation, is an indispensable "invisible cornerstone" in the entire process chain. It must maintain extremely high flatness, stable conductivity, and precise dimensional consistency in extreme environments such as vacuum, high temperature, strong electric fields, or chemical corrosion. This ultimate control over the microscale is the core value of high-end wafer mounting plates.

The reliability of wafer mounting plates stems primarily from the deep integration of materials science and structural design. High-quality mounting plates are typically made of high-purity ceramics, special alloys, or composite materials. These substrates not only possess excellent thermal stability, maintaining dimensional stability under drastic temperature changes, but also have controllable conductivity or insulation properties to adapt to different process requirements—for example, electrostatic chucks need uniform charge distribution to firmly attach wafers, while some inspection stages require complete electrical isolation to avoid signal interference. The materials are free of pores and impurities, ensuring no release of particles or gases in high-vacuum or cleanroom environments, preventing contamination of the wafer surface.

At the manufacturing level, precision control is maintained at every stage from raw material to finished product. Advanced CNC machining centers and ultra-precision grinding machines ensure mirror-like flatness of the mounting plate surface, ensuring uniform stress throughout the process and preventing photolithography defocusing or uneven film thickness due to localized warping. Details such as edge chamfering, vacuum channels, and positioning pin slots are optimized through fluid dynamics and stress simulation to ensure adsorption stability while preventing turbulence disturbances or stress concentration. Each finished product undergoes multiple tests, including laser interferometry, coordinate measuring machine (CMM), and surface resistance testing, to ensure its geometric and electrical properties meet stringent standards.

More importantly, customization capabilities provide broad process adaptability. Different manufacturing processes have vastly different requirements for mounting boards: some require integrated heating or cooling channels for precise temperature control, others require embedded sensors to monitor wafer status in real time, and still others require special coatings to resist plasma erosion. Leading manufacturers can provide one-stop solutions, from material selection and structural design to surface treatment, tailored to the customer's specific equipment model, process parameters, and wafer size, ensuring seamless integration between the mounting board and the entire system.

Furthermore, long-term stability is equally crucial. In hundreds or even thousands of process cycles, the mounting board must repeatedly withstand the mechanical impact of wafer loading and unloading, chemical erosion, and high-temperature baking. High-quality products, through surface hardening, anti-adhesion coatings, or self-cleaning structural designs, effectively delay performance degradation, reduce maintenance frequency and replacement costs, thereby improving overall production line efficiency.

Ultimately, the value of a wafer mounting plate lies not in its appearance, but in how it silently safeguards the creation of a chip in the unseen microscopic world. When a laser beam is precisely focused on the wafer surface, when an atomically thin film is uniformly deposited, when billions of transistors are arranged in an orderly fashion within a small space—it is the mounting plate that makes all of this possible with its near-perfect flatness and stability. Because in the philosophy of semiconductor manufacturing, true precision is not about pursuing the ultimate, but about ensuring that every repetition is as accurate as the first.

The reliability of wafer mounting plates stems primarily from the deep integration of materials science and structural design. High-quality mounting plates are typically made of high-purity ceramics, special alloys, or composite materials. These substrates not only possess excellent thermal stability, maintaining dimensional stability under drastic temperature changes, but also have controllable conductivity or insulation properties to adapt to different process requirements—for example, electrostatic chucks need uniform charge distribution to firmly attach wafers, while some inspection stages require complete electrical isolation to avoid signal interference. The materials are free of pores and impurities, ensuring no release of particles or gases in high-vacuum or cleanroom environments, preventing contamination of the wafer surface.

At the manufacturing level, precision control is maintained at every stage from raw material to finished product. Advanced CNC machining centers and ultra-precision grinding machines ensure mirror-like flatness of the mounting plate surface, ensuring uniform stress throughout the process and preventing photolithography defocusing or uneven film thickness due to localized warping. Details such as edge chamfering, vacuum channels, and positioning pin slots are optimized through fluid dynamics and stress simulation to ensure adsorption stability while preventing turbulence disturbances or stress concentration. Each finished product undergoes multiple tests, including laser interferometry, coordinate measuring machine (CMM), and surface resistance testing, to ensure its geometric and electrical properties meet stringent standards.

More importantly, customization capabilities provide broad process adaptability. Different manufacturing processes have vastly different requirements for mounting boards: some require integrated heating or cooling channels for precise temperature control, others require embedded sensors to monitor wafer status in real time, and still others require special coatings to resist plasma erosion. Leading manufacturers can provide one-stop solutions, from material selection and structural design to surface treatment, tailored to the customer's specific equipment model, process parameters, and wafer size, ensuring seamless integration between the mounting board and the entire system.

Furthermore, long-term stability is equally crucial. In hundreds or even thousands of process cycles, the mounting board must repeatedly withstand the mechanical impact of wafer loading and unloading, chemical erosion, and high-temperature baking. High-quality products, through surface hardening, anti-adhesion coatings, or self-cleaning structural designs, effectively delay performance degradation, reduce maintenance frequency and replacement costs, thereby improving overall production line efficiency.

Ultimately, the value of a wafer mounting plate lies not in its appearance, but in how it silently safeguards the creation of a chip in the unseen microscopic world. When a laser beam is precisely focused on the wafer surface, when an atomically thin film is uniformly deposited, when billions of transistors are arranged in an orderly fashion within a small space—it is the mounting plate that makes all of this possible with its near-perfect flatness and stability. Because in the philosophy of semiconductor manufacturing, true precision is not about pursuing the ultimate, but about ensuring that every repetition is as accurate as the first.