-

2026-01-26 2026-01-26

Can wafer mounting plates support the stringent requirements of semiconductor manufacturing with micron-level precision?

In the highly precise industrial field of semiconductor manufacturing, even a deviation of one nanometer can affect chip yield and performance. -

2026-01-12 2026-01-12

How can the layout of an electronic wafer mounting plate be optimized to reduce interference loss during signal transmission?

The layout of the wafer mounting plate needs to be coordinated with the overall system, taking into account interface layout, connector matching and EMC compatibility. -

2025-12-31 2025-12-31

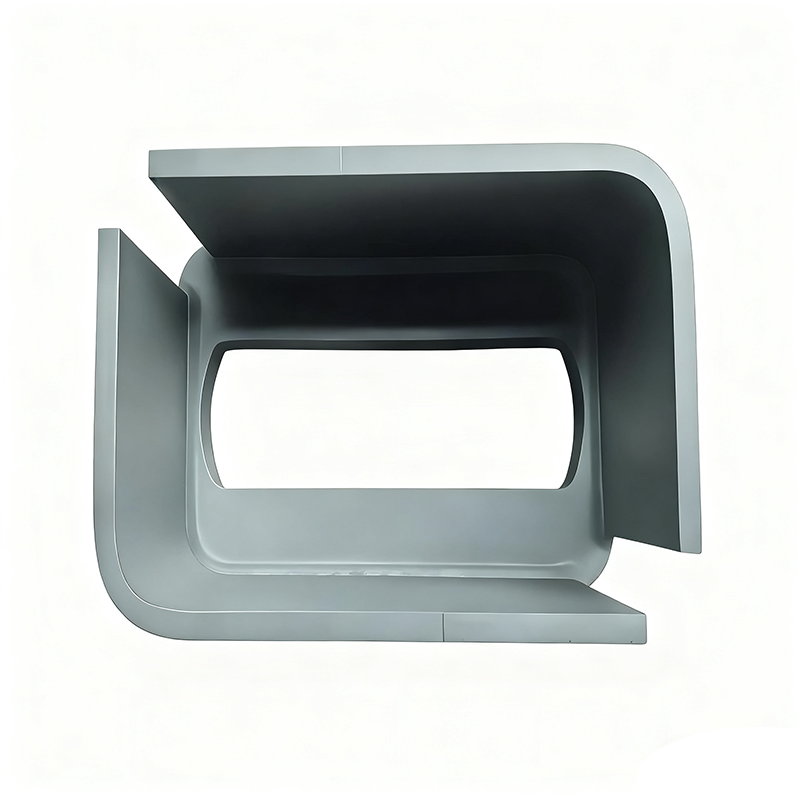

Why is custom casting the preferred choice for complex structural components over welding or machining?

In heavy machinery, energy equipment, rail transportation, and even precision industrial equipment, many critical components often possess irregular curved surfaces, internal cavities, multi-directional branches, or alternating thicknesses. -

2025-12-19 2025-12-19

Will the wafer mounting plate remain free from cracking, delamination, or degradation of adhesion performance under long-term use?

In the precision world of semiconductor manufacturing, the wafer mounting plate (Wafer Chuck), while not directly involved in circuit pattern formation, is an indispensable "silent foundation" throughout the entire process. -

2025-12-05 2025-12-05

What are the differences in formability, weldability, and cost among different metal materials in sheet metal customization?

In the field of sheet metal customization, material selection is the primary factor determining product performance, process feasibility, and economics. -

2025-11-19 2025-11-19

In the design of electronic wafer mounting plates, how can structural optimization simultaneously meet the requirements of high heat dissipation and low thermal expansion coefficient?

Simultaneously, to avoid mechanical stress or even cracking between the wafer and substrate caused by temperature changes, the wafer mounting plate must also possess extremely low thermal deformation characteristics.